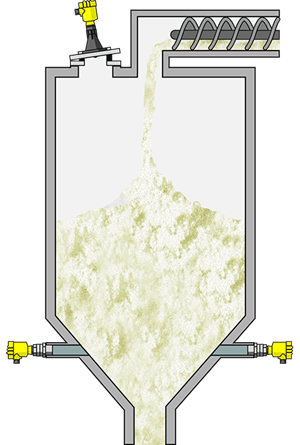

乙醇生产原料中间储罐

中间储罐料位及限位测量

过程数据

测量任务:

料位测量,限位测量

测量点:

筒仓

测量范围至:

0 … 15 m

介质:

谷物磨粉

过程温度:

-20 … +40 °C

过程压力:

0 … 0 bar

特殊挑战:

设备组件的机械负载,强粉尘,连续运转

应用范围

在乙醇生产过程中,为了保证后续工段有足够的原材料,需要将粉碎后的原料粉末储存在中间储罐中。用于乙醇生产的谷物在磨粉机中变成粉末后,就直接送往粉料仓暂时储存。因为原料的进出量巨大,筒仓及内装件承受的压力非常高。采用料位测量仪表,可保障生产连续进行以及设施高效运转。

您的获益

可靠

料位测量避免设施过载,实现安全运行

经济

生产连续不间断,提升经济效率

方便

仪表带吹扫,可在严重积垢时进行自动清洁

关闭