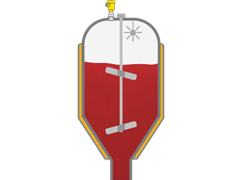

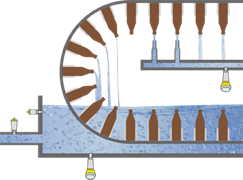

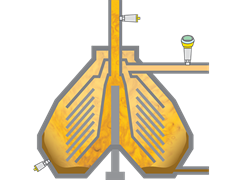

For liquids

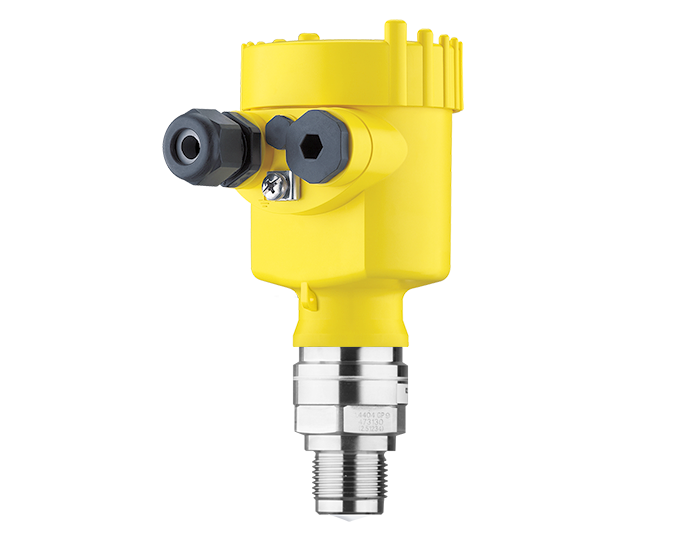

VEGAPOINT

Capacitive level switches for the detection of water-based liquids and light bulk solids

Vibrating level switches

Ceramic measuring cell

Metallic measuring cell

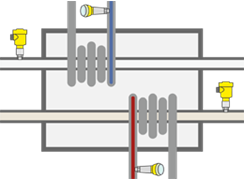

Standardised hygienic adapter for level, pressure and point level sensors

Any common adapter system that complies with EC 1935/2004, FDA, EHEDG, 3-A can be used for level sensors as well as for pressure and point level sensors. Whether all metallic or with elastomer O-ring sealing: The sensors fit all standard, commercially available hygienic connections.

- Flexible and simple integration

- Fast exchange

- Reduced production downtime

- Fewer instrument versions in stock

No. 929 Fenghua Road

314036 Jiaxing, Zhejiang Province

China

Tel.: 400 881 9190

Fax: +86 22 26273297

marketing.cn@vega.com

www.vega.cn

Callback service

Ask for one of our experts to call you back.

Request a return callIn urgent service cases, please contact us directly via our 24-hour service hotline.

News, events and more

Blog articles on the subject of food

Events dealing with the subject of food

Videos on the subject of food

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

We need your consent

This content is provided by an external provider. If you activate the content, personal data may be processed and cookies set.

Close